ENSURE YOUR DESIGN SPECIFICATIONS ARE IMPLEMENTED ON SITE

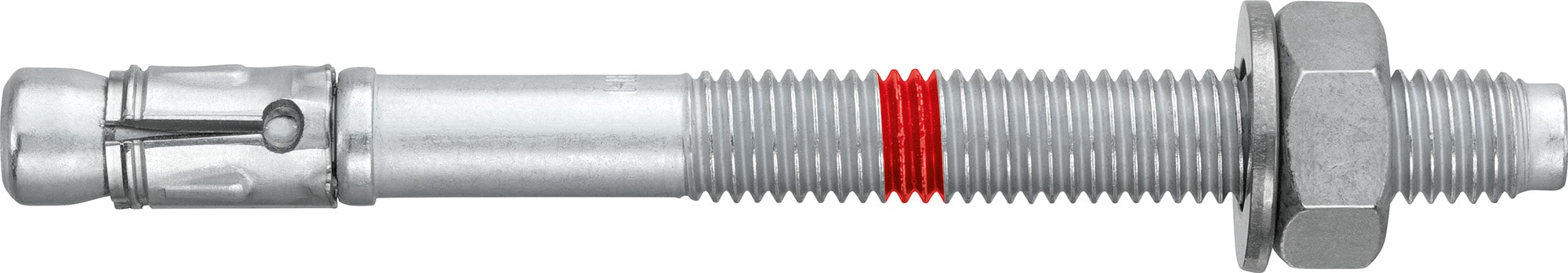

Specifying Hilti’s HST3 expansion anchors along with our intelligent, cordless impact wrench means installed as per design

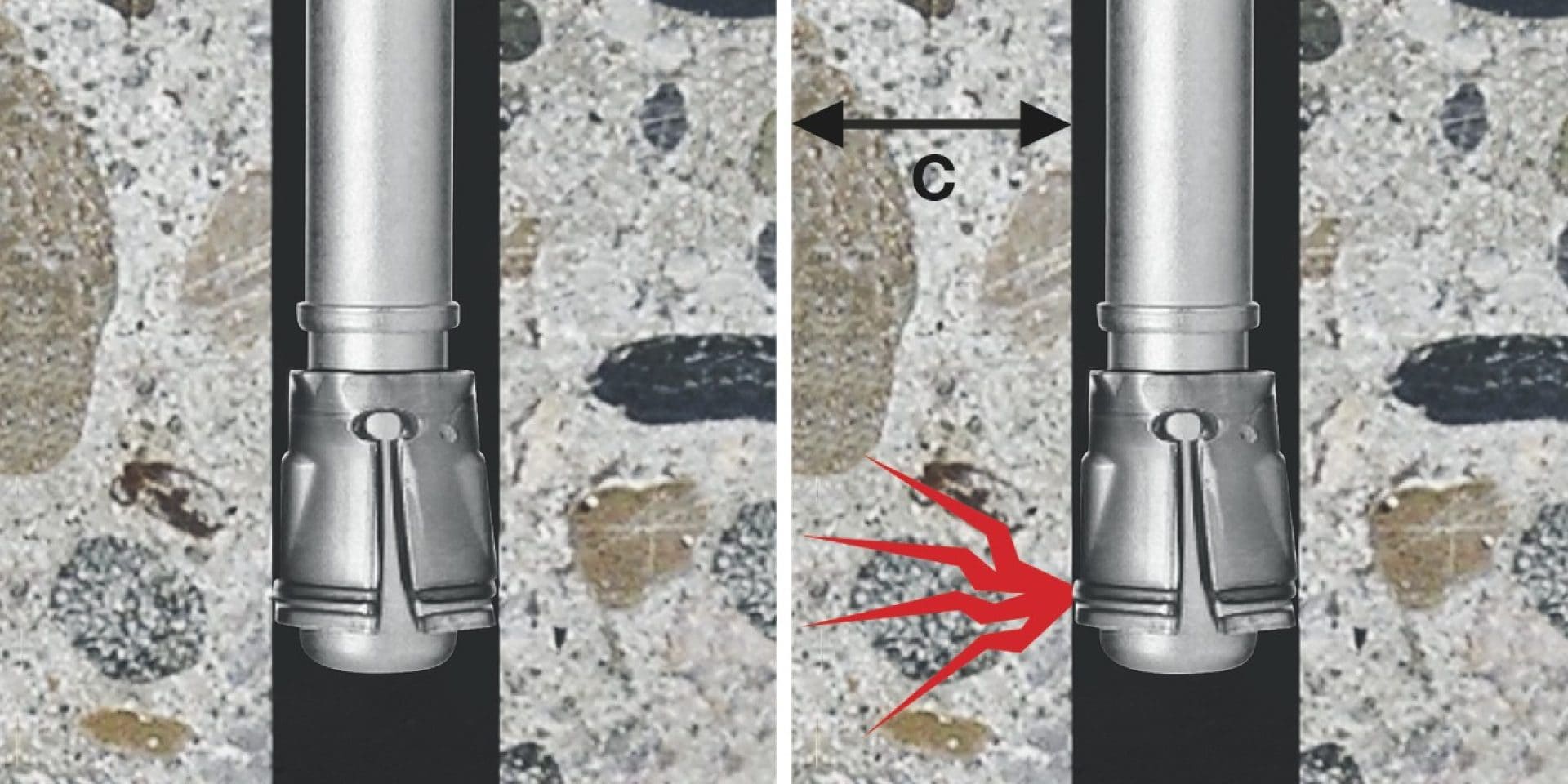

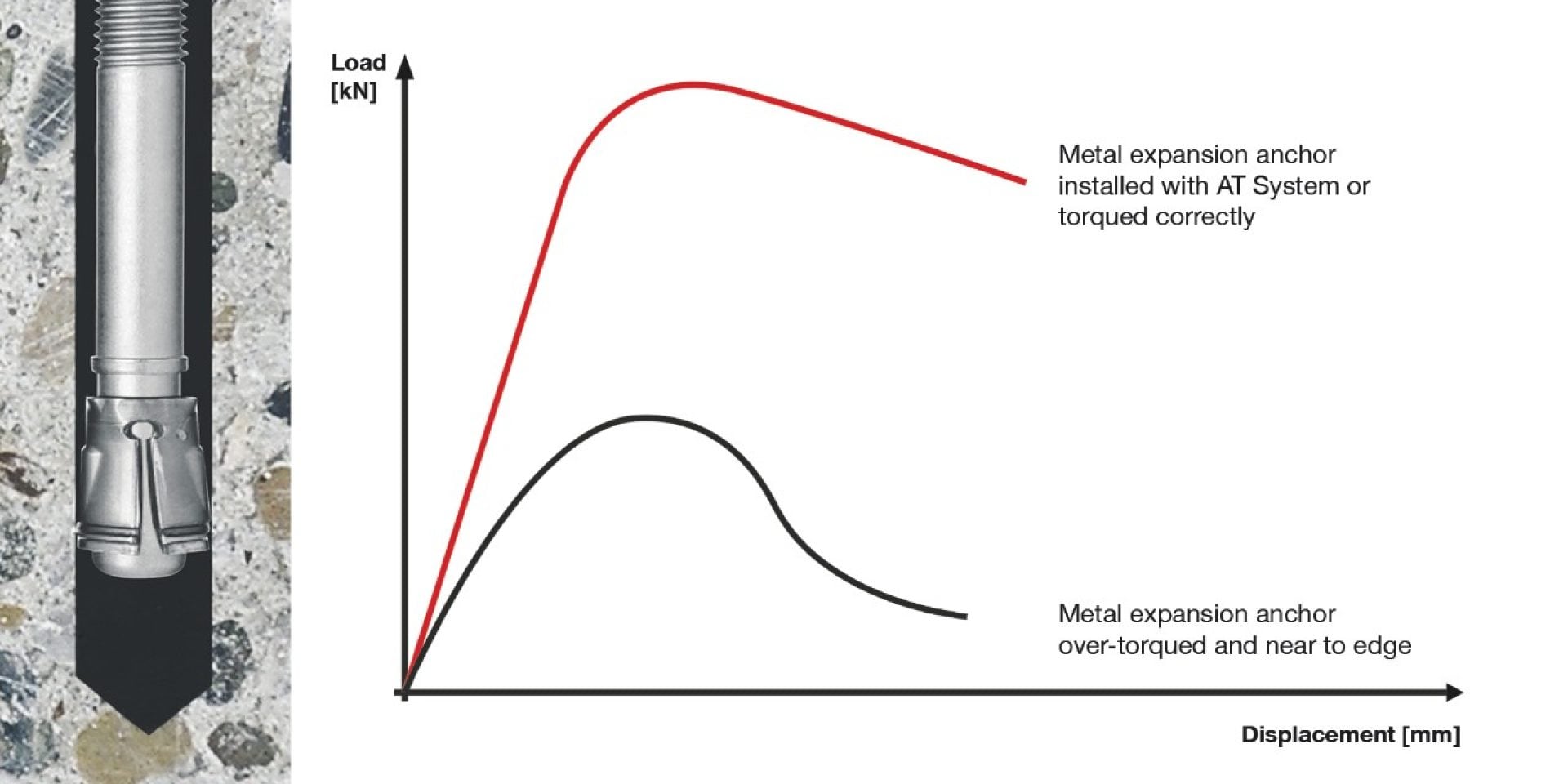

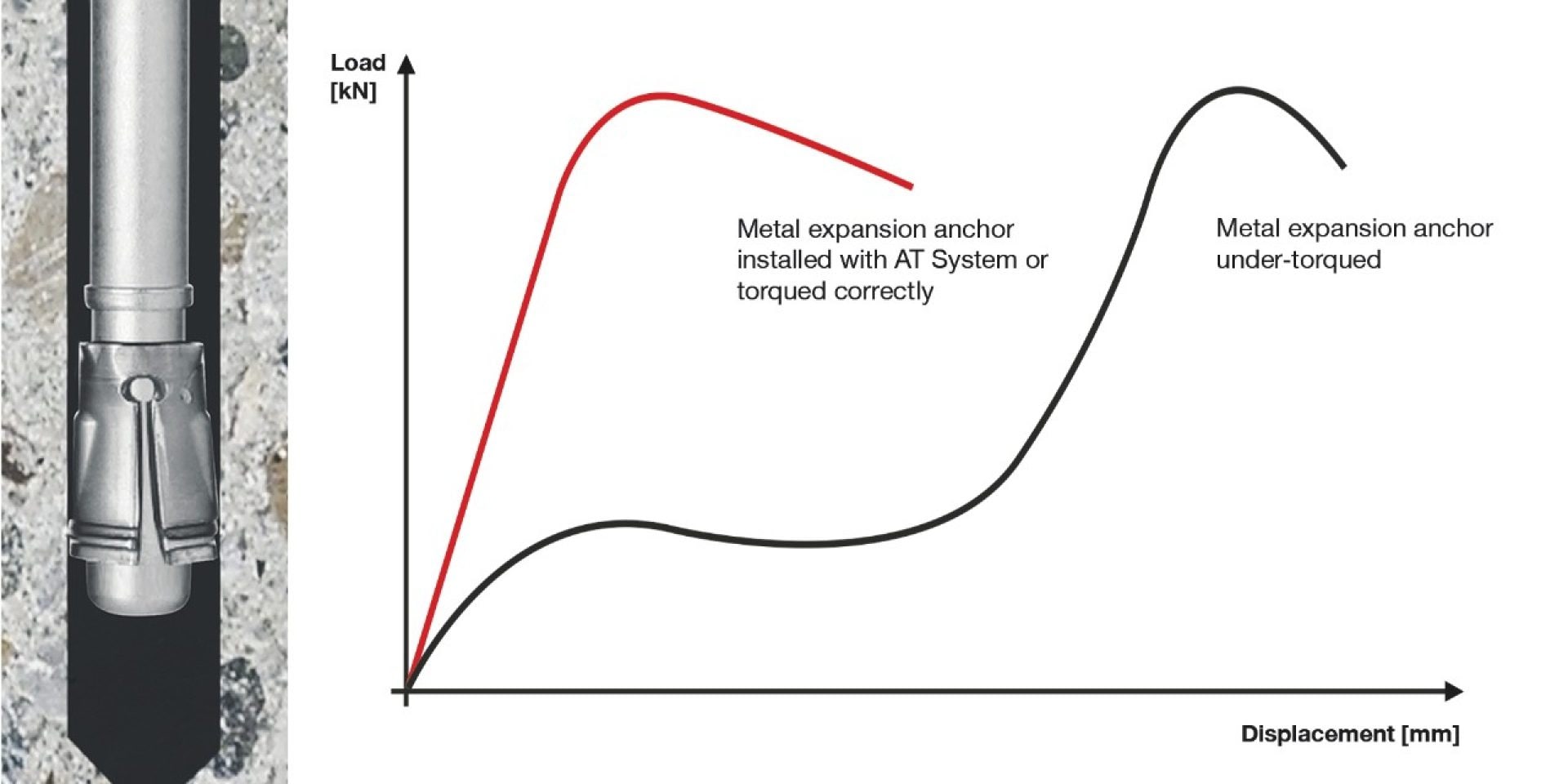

Torque: hard to see; easy to neglect. Applying the right torque is critically important to achieve the performance of a torque-controlled expansion anchor. Put bluntly, if an anchor is not set with the manufacturer’s recommended torque, it is only a matter of time before defects creep in. In fact, the American Construction Inspector Association (ACIA) ranks over-and under-torqued anchors as the number-two reason for failed jobsite inspections.

There are many reasons why anchors are not installed as per the manufacturer’s recommendations on job sites. Foremost among them is speed: with scheduling pressure constantly increasing, finding the time to carefully torque and check every single anchor is practically impossible. Furthermore, experienced jobsite professionals with the necessary specialized training are not always on hand.