- Home

- Business Optimization

- Solutions

- SPEC2SITE

Spec2Site: Our commitment to engineers and contractors

From structural connection design to onsite installation, we are your partner in productivity, safety, and sustainability

What is SPEC2SITE?

With our SPEC2SITE solutions, we aim to improve every step of the construction workflow by connecting design specifications with the jobsite to enable precise installations. We offer solutions for structural connections, MEP support systems, and fire protection, delivering value through four key elements:

- Higher performing hardware matched with the right design methods

- Design software and design-related services

- Digital content for on-demand and live learning through our Engineering Center

- Onsite support through our direct sales and engineering teams

For engineers, our SPEC2site solutions help you make better specifications that are:

- higher performing to meet a wide variety of applications challenges and requirements

- value engineered and code-compliant thanks to our design methods and software

- offering more peace of mind with better site practices, knowledge sharing, and jobsite presence

- more sustainable with reduced materials and quantifiable reductions in CO2

For contractors, our spec2SITE solutions help enable better jobsite practices that are:

- faster with fewer installation steps, allowing for a reduction of the total cost of ownership (TCO)

- simpler thanks to more intuitive installation processes that require less skilled labor

- safer with installations enabled by our systems, knowledge sharing, and jobsite presence to help make your work comply with specifications

- more sustainable with reduced materials and quantifiable reductions in CO2

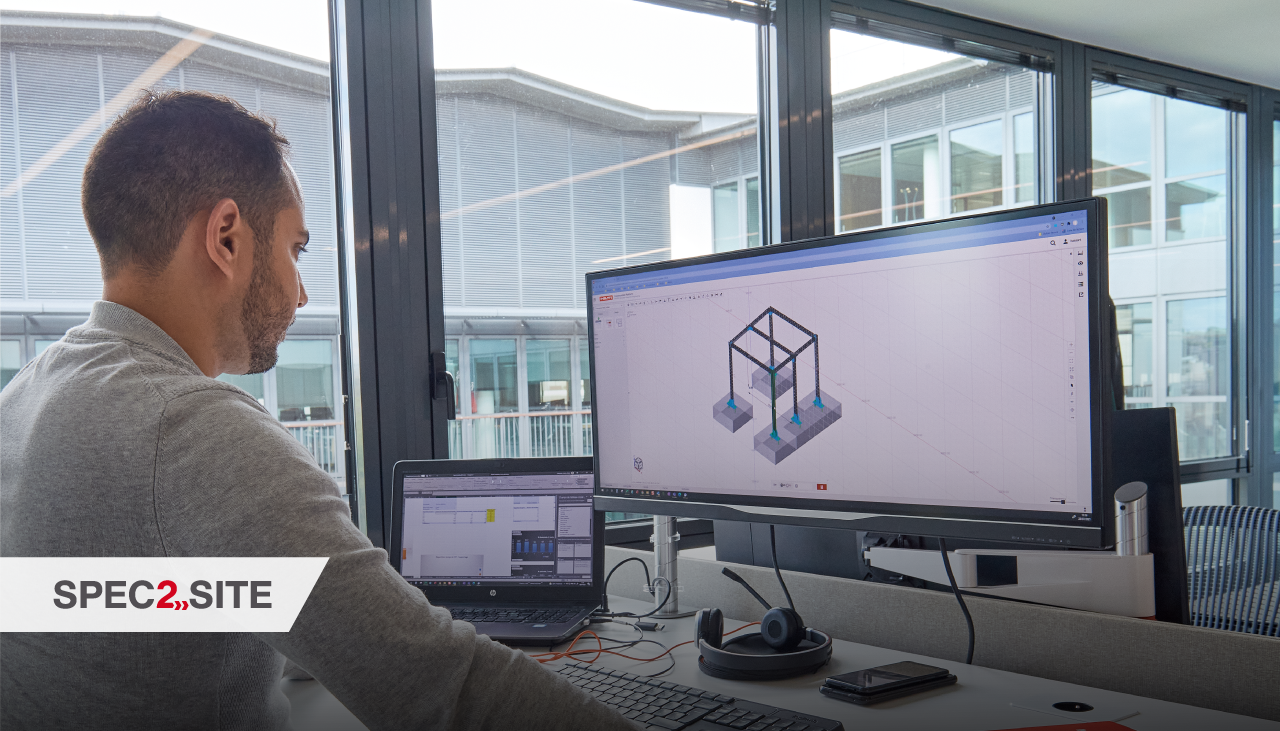

Spec2site solutions for engineers

We'll help you deliver specifications that are higher performing and value engineered, giving you more peace of mind and more sustainable designs.

Discover just some of our higher performing anchoring systems

HST4-R stainless steel wedge anchor

Do more with less with our highest-performing stainless steel wedge anchor.

Designed for bearing high static and seismic loads in cracked concrete both indoors and outdoors, this anchor features a patented anti-spin expansion cone that helps eliminate spinning issues for a more reliable installation.

Value engineered

Enabled by application-based, easy-to-use software

When optimizing structural designs, engineers must consider parameters such as safety, productivity, special loading conditions, sustainability, ease of design, and ease of execution.

Our easy-to-use design software, PROFIS Engineering Suite, helps you value engineer your designs based on your application requirements and degrees of freedom. We embed our higher performing hardware and the latest design methods into our software, enabling you to quickly create code compliant designs with lower Total Cost of Ownership (TCO).

PROFIS Engineering also seamlessly connects to various structural design softwares. You can import design cases and export value-engineered designs that hold throughout the construction workflow, reducing the need for re-design.

How can PROFIS make your design process easier?

Design

Comprehensive anchor, baseplate, and rebar design

- Save up to 60 minutes per design

- Analyze your baseplate thickness using AISC DG1 or finite element analysis and reduce its size

- Value engineer designs by reducing anchor or rebar diameter, embedment depths, or other design parameters

Export

BIM/CAD exports

- Save up to 15 minutes per design export

- Configure baseplates to REVIT and TEKLA using the direct plug-in

- Export CAD

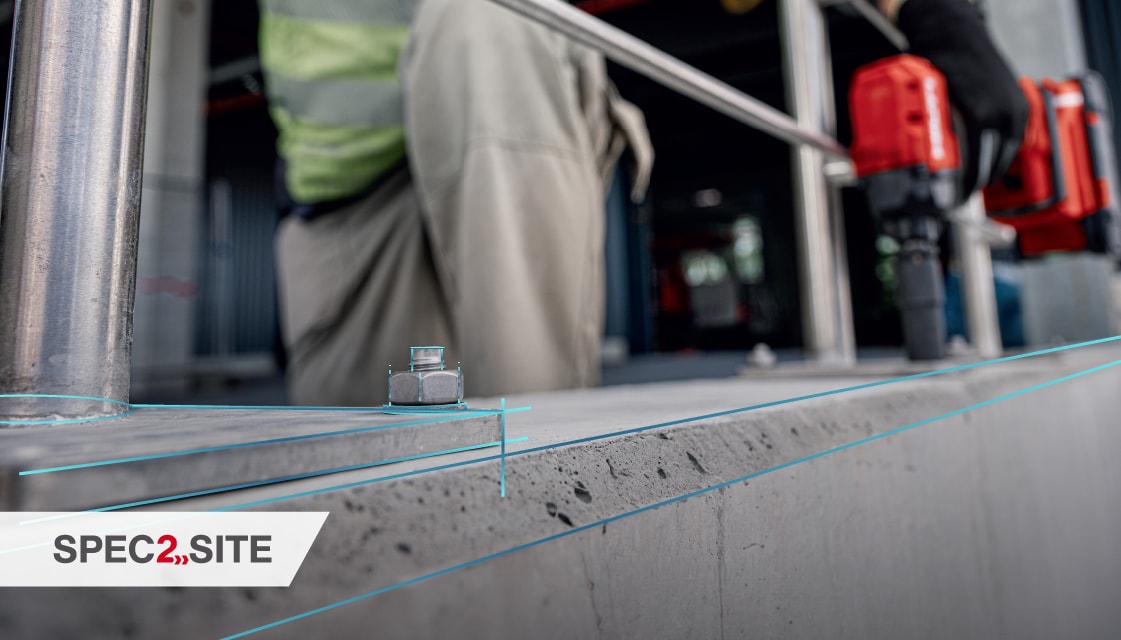

More peace of mind

spec2SITE solutions help you get what you specify on the jobsite

Proper design is one aspect of ensuring that a structural connection meets its performance requirements. However, it must be combined with proper installation on the jobsite.

During installation, various critical parameters come into play – such as borehole cleaning, accurate mortar dosing, and correct torquing – to ensure each anchor performs optimally.

Do you want more peace of mind that the structural connections you design are properly installed? Hilti’s spec2SITE solutions help make installations faster, simpler, safer and more sustainable. With systems that combine with our onsite support, we help ensure you get what you spec.

More sustainable

We'll support you in reducing your impact and delivering measurable results

Are you facing a growing challenge to report the environmental impact of your projects?

Our SPEC2site systems deliver sustainability transparency through Environmental Product Declarations (EPD) and Life-Cycle Assessments (LCA) which are standardized, verified documents reporting a product's environmental impact. They're also needed to meet the requirements of green building certifications on projects.

In addition to incorporating low-label chemical mortars and less carbon-intensive raw materials, our SPEC2site solutions offer opportunities for value engineering that help you reduce steel consumption, mortar volume, and onsite waste.

Where can our SPEC2site solutions help you?

Steel to concrete baseplate connections

HST4 expansion anchors for higher loading in cracked concrete and Adaptive Torque installation

Hollow drill bit for saving installation time PROFIS Engineering software to optimize your baseplate design more quickly and easily, even under seismic loading conditionsSpec2site solutions for contractors

Get help making structural connections faster, simpler, safer, and more sustainable. With our spec2SITE solutions, you'll benefit from up to:

less time per borehole *

when drilling and cleaning

less mortar waste *

when injecting mortar

less torquing time *

with Hilti's Adaptive Torque module

Skip manual cleaning of drilled holes

Reduce installation steps with solutions that enable automatic cleaning or do not require cleaning

- Automatic borehole cleaning: Combine hollow drill bits with a Hilti vacuum cleaner to eliminate the need for time-consuming and error-prone manual cleaning.

- Solutions that do not require cleaning: Choose anchors approved for use without borehole cleaning.

Our fastening solutions range from chemical to mechanical to cast-in, covering the most challenging jobsite conditions and applications, like seismic loading and wet concrete conditions.

Take control of adhesive anchor consumption and create less waste

Know exactly how much mortar you are using on the jobsite

- Use our cordless adhesive anchor dispenser to cut waste – inject only the amount you need.

- Choose foil capsule solutions for faster and more precise installations.

Make it easier to torque anchors

Torque in line with approvals or technical data with the Adaptive Torque system

Use our Adapative Torque (AT) system for simpler, faster installation. Reduce your torquing time up to 80% and minimize the risk of under- or over-torquing your fastening applications.

Designed for easy use, including by less experienced workers, the AT system combines an impact wrench and a smart torquing module to help you torque correctly every time.

What applications are covered by our spec2SITE solutions?

Baseplate

- Steel and metal – column and beams, platforms and mezzanines, staircases, and more

- Façade – top of slab brackets and front of slab connections

- Industrial equipment – machine, equipment, and warehouse racking fastening and more

- Civil – tunnel signs, earth retaining structures, and more

Rebar

- Extensions of beams, slabs, columns, and walls

- Joints between beams, columns, slabs, and walls

- Strengthening of concrete elements using overlays or jacketing

* All claims are based on internal research data. Actual results may vary depending on individual conditions. Contact Hilti for more information.