Independent studies have identified poor construction procedures as one of the main causes of structural failure, while the American Construction Inspector Association reveal that over-and under-torqued anchors are the number-two reason for failed jobsite inspections.

And maybe it is no wonder, when the available tools do not match the current demands. To correctly install an anchor your choices are between a slow and imprecise torque wrench, cumbersome torque bars or a powered impact wrench, which lets productivity soar while safety and reliability slump.

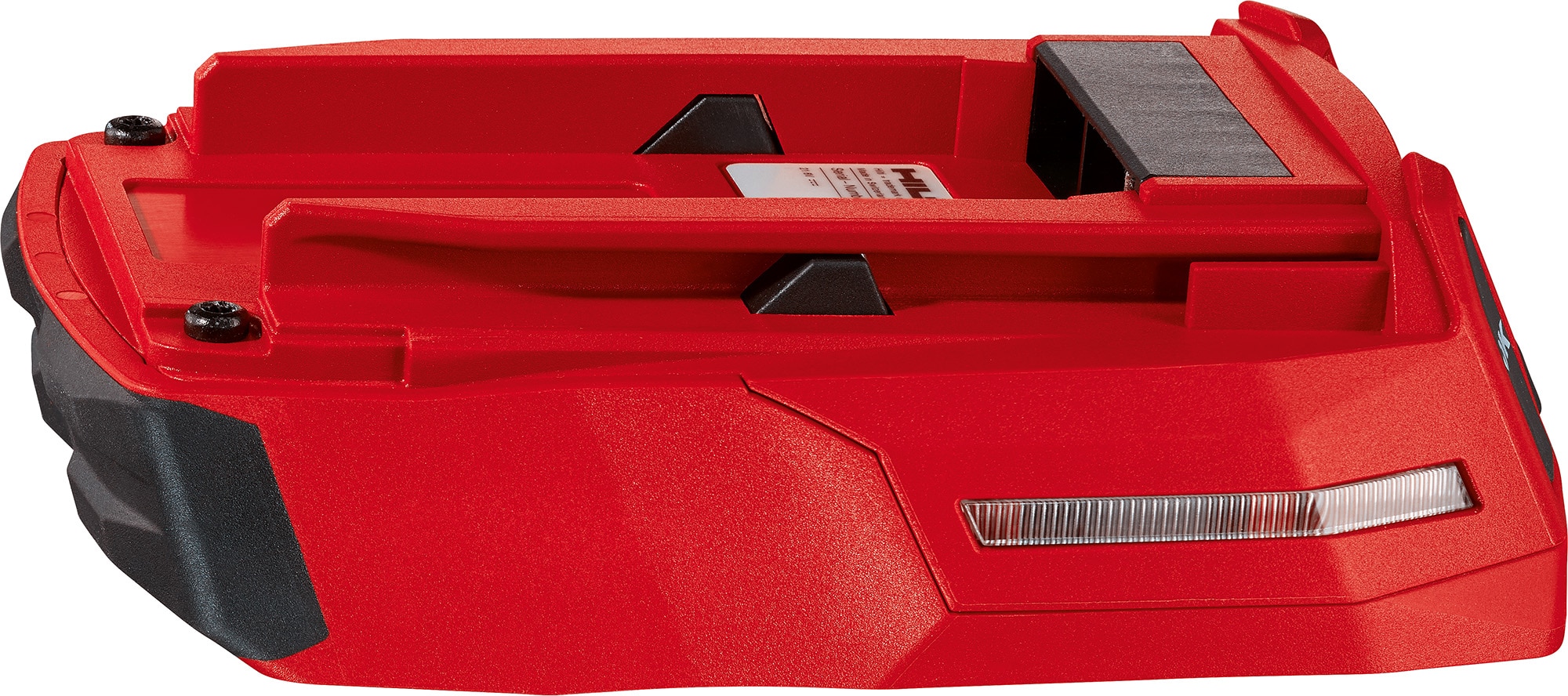

Now, with Hilti's certified solutions in Adaptive Torque (AT) system and innovative Torque Limitation Nut , you don’t have to compromise.

Adaptive torque system -Simple, Fast, Effective

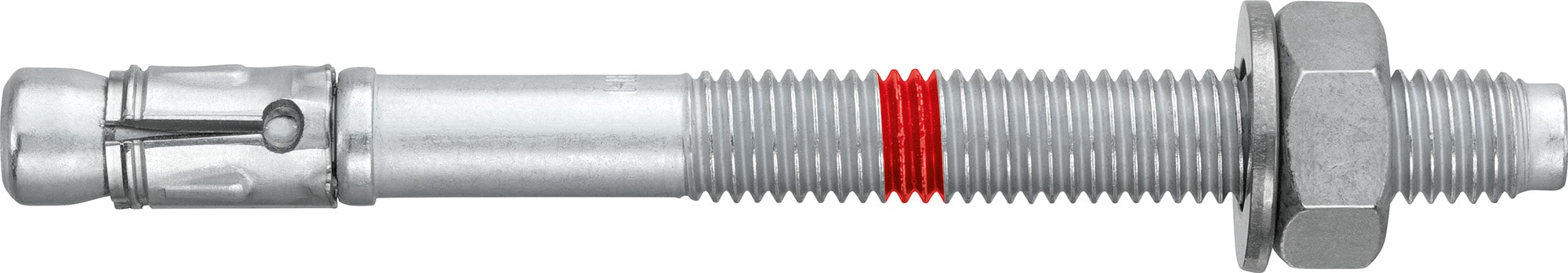

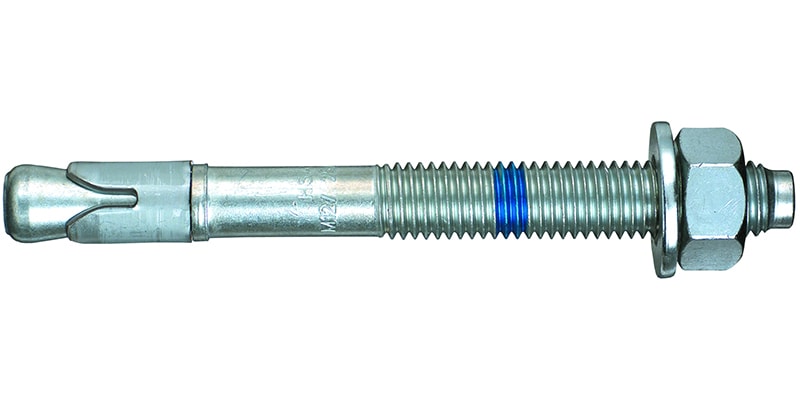

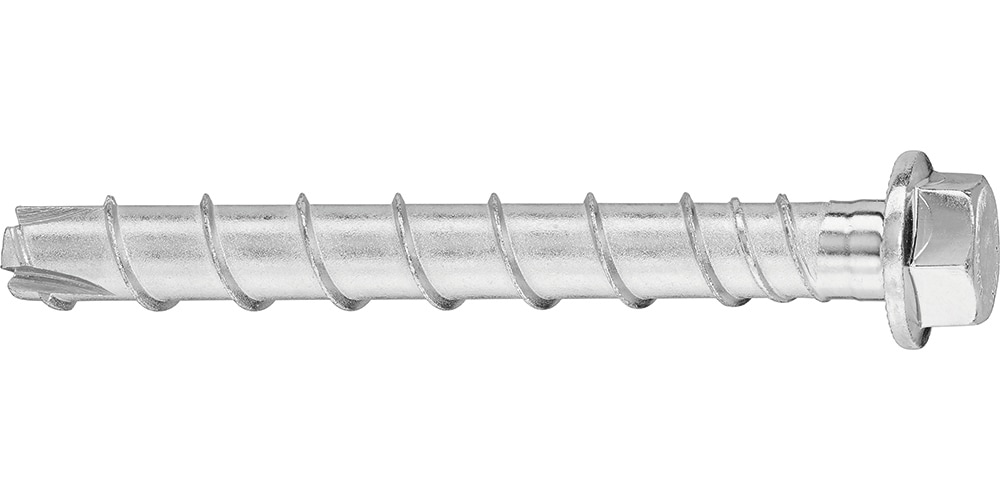

Select your anchor

Use the SI-AT-A22 module’s built-in scanner to read the barcode on your box of anchors. The SIW 6AT-A22 impact wrench then adjusts the torque setting to meet certification requirements. Tap the lock button to confirm your selection, and the impact wrench is ready to use.

Learn More about SI-AT-A22 modulePull the trigger

With the SIW 6AT-A22 impact wrench, all you need to do is pull the trigger and let the tool work. As soon as the SI-AT module lights up green, you know the anchor has been torqued to exactly the right level to comply with ETA approvals.

Learn More about SIW 6AT-22Adjust and retorque

Giving you confidence that the anchor has been correctly installed, sensors in the SIW 6AT-A22 recognize if an anchor has been loosened and, on retightening, will restore the correct torque. And with the AT System can you adjust and retorque up to three times.

Learn More about SI-AT-A22 module